SMART SHIP SOLUTIONS

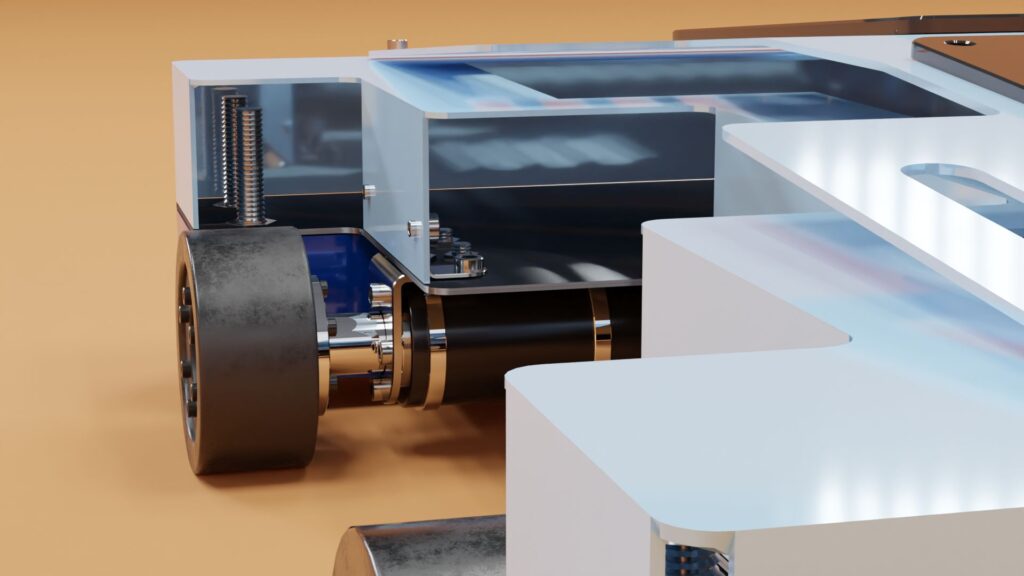

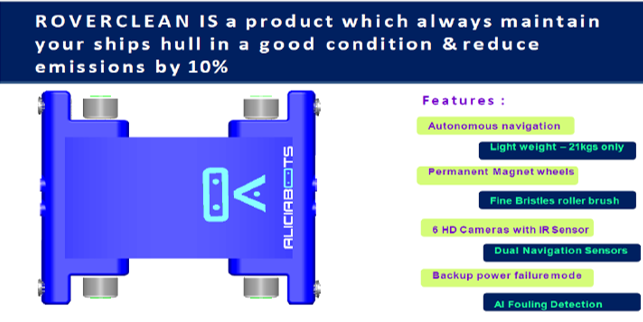

Robotic (Rover Clean) Underwater Hull Cleaning and Hull Inspection

-

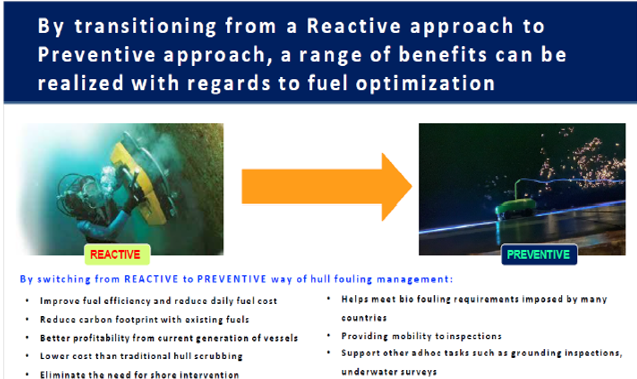

- Alicia bots has created an autonomous, self-cleaning robotic solution that makes it profoundly easier to keep ships and underwater structures clean.

- On ships, our robots travel along a fixed route, inspect for biofouling, clean, and then return to their deployment point.

- We’ve also created a second robot, capable of swimming, that is designed especially for cleaning underwater structures supporting ports, terminals, oil rigs, and offshore wind and solar farms.

- When used along with our proprietary treatment plant technology, biofouling material can be collected then transformed into potable water and bio oil.

Anti Fouling Coating Saving Cost

- Saving Cost Up to 50% for Fouling Coating

- Save time for Sandblasting

- Steel plate will use for a long time

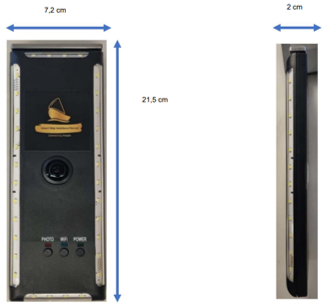

DS Camera

Automatoc Photographic Device for Marine Engine Cylinder

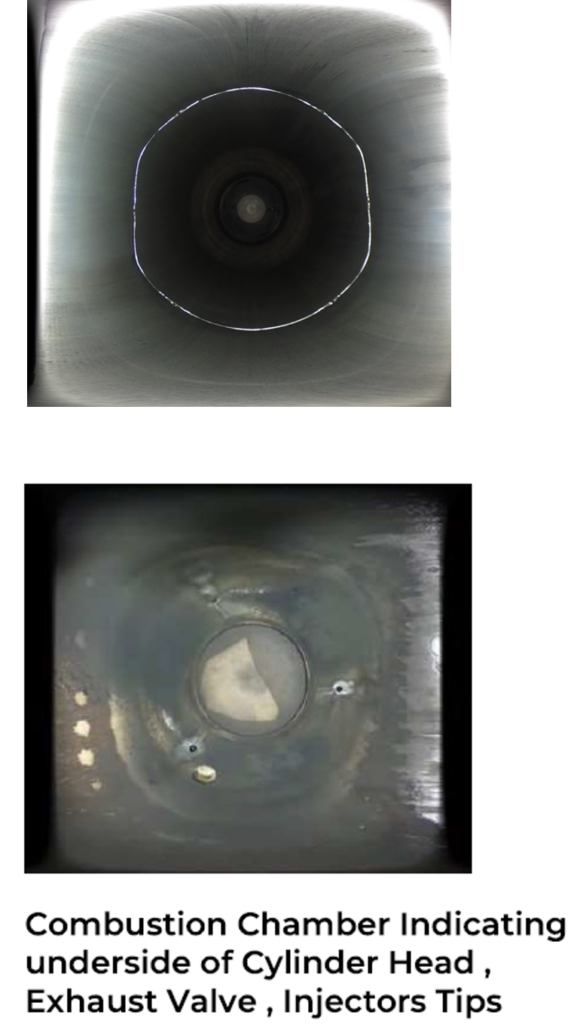

The DS CAMERA is a tool/camera that can be used for the following purposes:

1. Inspection of Cylinder Liner condition

2. Inspection of valve leakage condition

3. Inspection of the condition of the combustion chamber, whether it is optimal or not

4. Inspection of the condition of fuel output from the injector

All of these aspects can be assessed without the need for disassembly.

The DS CAMERA can only be utilized on 2-stroke engines with a minimum bore diameter of 350 mm.

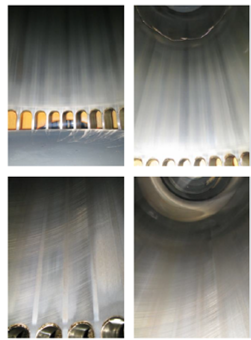

Good Liner Condition

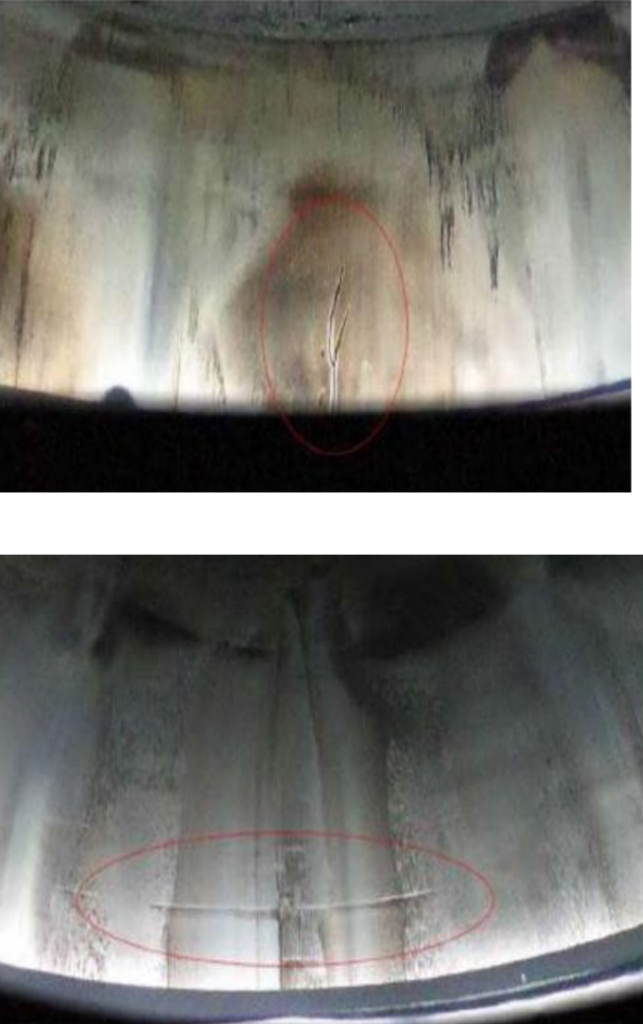

Discovery of defects in the liner

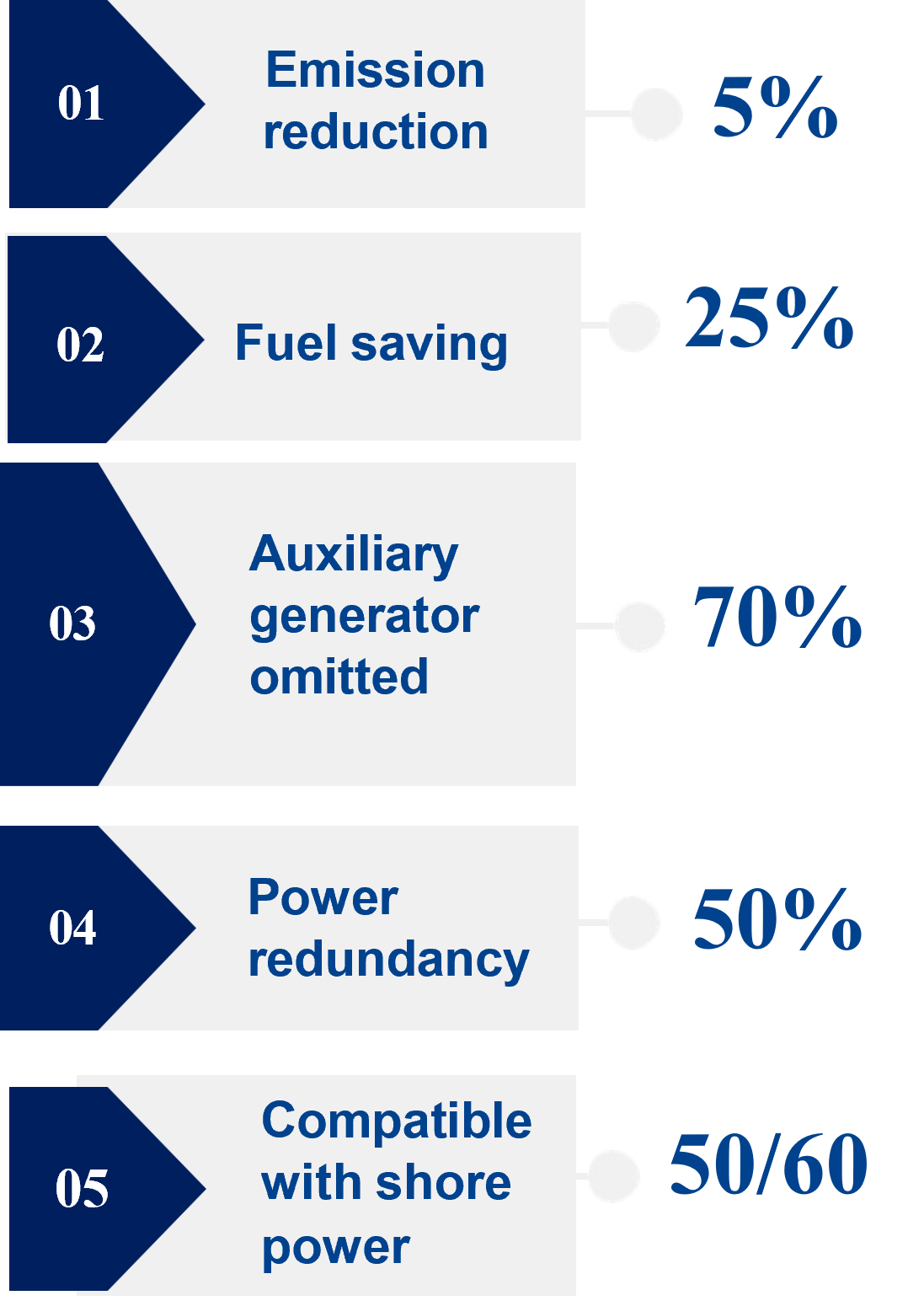

Innovative Shaft Generator System Solution

Benefits of Installing Shaft Generator System

PTI Hybrid + PTH Electric Propulsion

PTI diesel-electric hybrid power to improve ship power performance and redundancy.

PTH electric propulsion, electric propulsion in port or emergency conditions

Compatible with different electrical systems

When the ship berths and the shaft generator converter can realize the conversion of 50Hz/60Hz different power systems, saving the investment of ship shore power equipment.

EEDI/EEXI/CII

Improve the energy efficiency index of ships with lower costs and considerable benefits to meet the stage emission reduction targets, meet the port access conditions and save carbon tax.

Lower operating costs, high return rate

Utilize the surplus power of the main engine, significantly reduce the fuel consumption of power generation, and recover the investment cost in 1 year.

Auxiliary engines reduce for new ships and shut down for operating ships

The shaft generator can be used as the main generator to supply power independently/grid-connected. The newly designed ship can reduce the

number of auxiliary generators and save space; one auxiliary generator can be shut down in the operating ship, which can significantly reduce the

maintenance work, spare parts and lubricating oil for the auxiliary generator.

Contact

Jnkjaya@gmail.com

021 4585 9084

0815 8623 1959

PT JNK MATGIM

JL.Boulevard Barat Raya

RUKO INKOPAL BLOK G NO.59

Jakarta Utara, Provinsi DKI Jakarta

Indonesia

Phone : 021 45859084

0815 8623 1959

Email : jnkjaya@gmail.com